Connection Of Timber Beams 🪵🪵

Used Also For Roofs

Hi guys,

Today we’ll look at how we connect timber beams to beams or walls.

In fact, this connection type is often used to connect secondary to primary beams in a flat roof, which we covered last week.

💡💡 Info: All the verifications follow Eurocode.

The connection I am talking about is a steel hanger. The direct translation from Danish and German actually makes a lot of sense: Beam shoe. 👟👟

Ok, let’s get into how we design this connection:

Derive the loads acting on the connection (reaction forces from the secondary beam)

Set up timber and steel properties

Verification of steel plates to secondary beam and

Verification of steel plate to primary beam

#1 Derive loads

For this tutorial, I am assuming that you guys know how to calculate loads, derive the reaction forces from a simply supported beam and work with load combinations.

💡💡 If not, check out our article where we show it in detail: → Timber connection design ← 💡💡

Biggest reaction force:

Rd = 8.0 kN

#2 Set up timber and steel properties

Strength values like density of the timber, tensile strength of nails/bolts

Thickness of the steel plate

Dimensions of nails/bolts, timber beams

Amount of nails/bolts

Partial factors and k_mod

etc.

#3 Verification of steel plates to secondary beam

The first step is to calculate the characteristic withdrawal strength:

Withdrawal strength

Next, we’ll calculate the charact. embedment strength

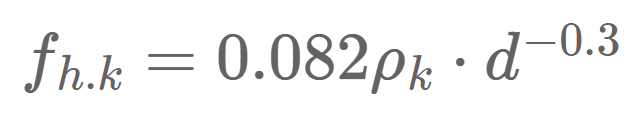

Characteristic embedment strength (EN 1995-1-1 (8.15))

But actually, many manufacturers provide this value.

🙏🙏 Before we move on, I want to recommend you reading up in Eurocode, why and how certain formulas are used. We can’t go into detail in this newsletter.

Characteristic yield moment (EN 1995-1-1 (8.14))

Again this value is often given by manufacturers.

Now, we can go ahead and calculate the resistances of the different failure modes. In our case we have 1 shear plane because we are using nails. Therefore, failure modes a, b, c, d and e apply. In case you use bolts, then modes j/l, k and m apply.

Failure mode a

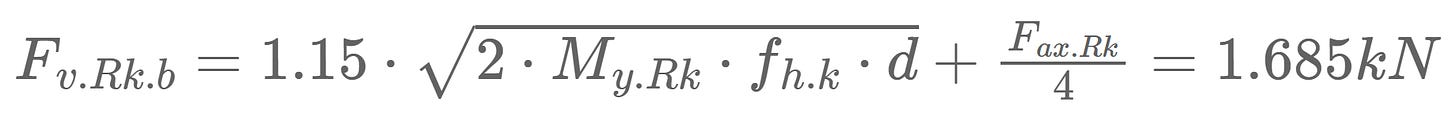

Failure mode b

Failure mode c

Failure mode d

Failure mode e

Now, take the smallest of these values as your connection resistance.

And multiply it with the number of nails you use.

Calculate the design resistance and check that the utilization ratio is < 100%

Et voilà, the plates connecting the secondary beams are verified. ✅✅

#4 Verification of steel plate to primary beam

Verifying the plate to the primary beam is exactly the same verification as #3. That’s why we save the space and save you time reading it. 😎😄

But finally, the steel hanger looks like this. 😍😍

Conclusion

You can follow this calculation step-by-step if you have to design a custom-made steel hanger. Because there are also many manufacturers which provide load bearing tables (Example). In that case, you would only need to verify that the resistance is > the design load acting on the connection.

That saves you a lot of time. 👍⌚

Hope you learned something new in this email.

And see you next week for another roof system. We have 2 more to go. 😄🚶

Cheers,

Laurin