Hi friends,

Today we are back at covering a roof system - the collar beam roof.😎😎

The timber collar beam roof consists of:

Rafters

Collar beam

Ridge board (optional)

Support system (ceiling joists or concrete slab)

A wind bracing system like steel rods or plywood boards

As for the other roof types, there are many different variants. Google a bit and you’ll discover different types of the collar beam roof.

Before we’ll get into the design calculations, let’s have a quick look at the static system. 👇👇

The static system consists of 2 inclined beams which are connected by a hinge at the top and by pin supports at the bottom. A horizontal beam/bar (collar beam) is connected to both beams by hinges. 👇👇

Alright, now we are ready. Here’s the step-by-step process we are following (it’s the same for all timber elements 😁😁):

Determine the characteristic loads (snow, wind, dead and live load)

Set up load combinations

Choose the timber material and geometry of the rafters and collar beam (width and height)

Calculation of the internal forces (normal force, shear force, bending moment)

ULS bending verification

ULS shear verification

SLS deflection verification

These are the steps, we need to follow to design the rafters and collar beam, but there is more to the roof structure such as connection design, wind bracing, and support verification.

#1 Characteristic loads

We’ve written detailed articles about loads on roof structures, which you can follow to understand how to calculate these loads:

#2 Load combinations

Load combinations combine the characteristic loads and add safety factors.

→ Detailed guide to load combinations ←

#3 Timber material and geometry of beams

You choose the timber material between structural wood and glulam. Glulam is usually stronger and can be delivered in almost any size, as it glues layers of timber together.

Just google a bit, and you’ll find the strength properties for both types of timber.

Before starting the calculation, we need to define the cross-sectional dimensions’ height h and width w of the beams to then calculate cross-section properties such as the moment of inertia.

Rafter dimensions:

#4 Internal force calculation

In uni, you learn to calculate the internal forces by hand, which is good to get an understanding for it. Later, as a structural engineer, you’ll mainly use software for it. Mainly because it’s a lot faster. Or, as in our case, it would be extremely difficult to calculate a statically indeterminate structure by hand. Programs like Autodesk Robot, Dlubal Rfem, Sofistik, etc. are used.

You apply the characteristic loads, and the programs generate automatically load combinations and the internal forces.

Here’s an example of the bending moment diagram due to the load combination from the picture above.

#5 ULS bending and compression verification

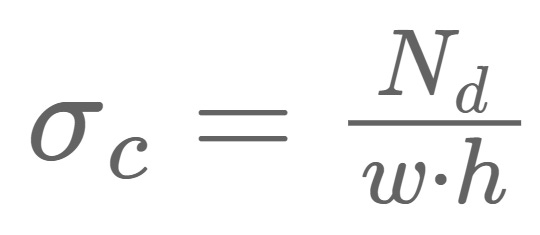

First, calculate the bending and compression stresses:

Then, the bending and compression resistance:

Now, check if the utilization ratio is < 100% (EN 1995-1-1 (6.19)) . ✅✅

To see the whole calculation with examples, check out our 👉 article 👈.

#6 ULS shear verification

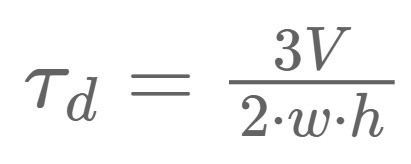

As for bending, we’ll calculate the shear stress and shear resistance.

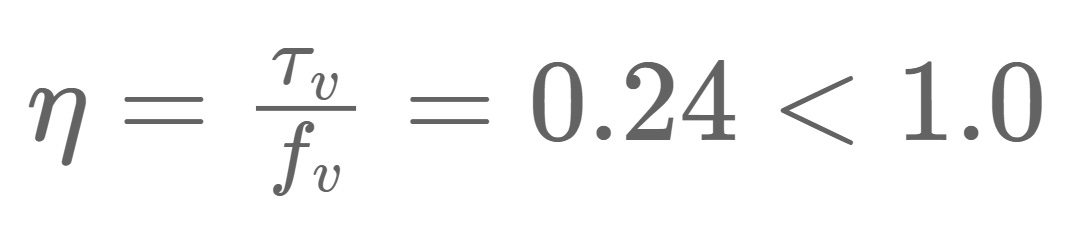

And then the utilization ratio.

#7 ULS buckling verification

Buckling can happen to all elements which act in compression. So both the rafters and the collar beam have to be verified for buckling.

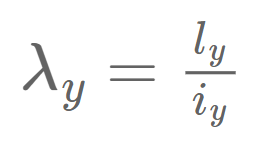

Slenderness ratio

Relative slenderness ratio

Instability factor

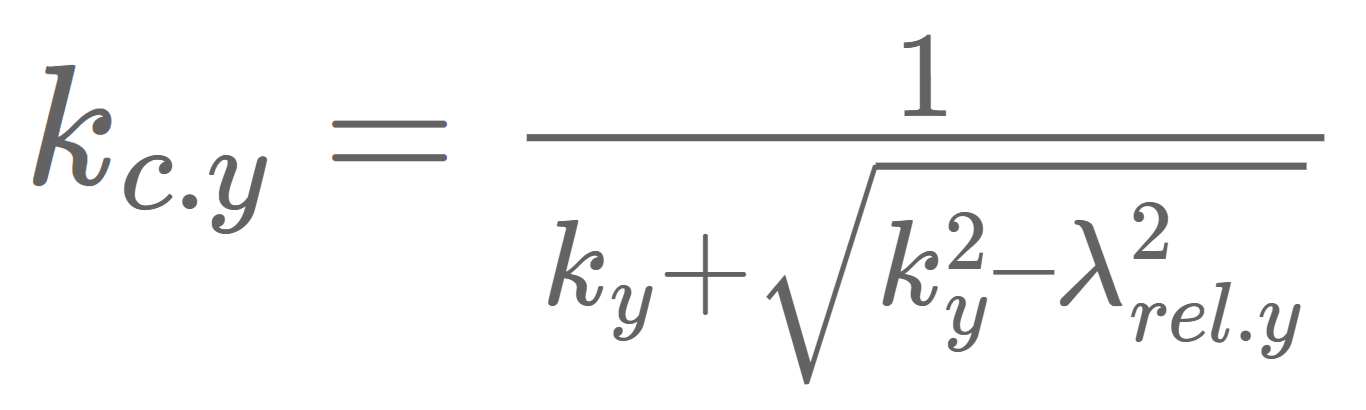

Buckling reduction coefficient (EN 1995-1-1 (6.25))

Utilization ratio (EN 1995-1-1 (6.23))

#8 SLS deflection verification

The deflection is also calculated with structural analysis programs and checked against limits from either Eurocode or the client.

It’s a bit more tricky, I recommend reading the article for more detailed explanations. 😎😎

This was the 4th (and 2nd last 😜😜) timber roof system. Hope you also liked this one.

So be ready for the last and final timber roof system next week. ✌️✌️

Cheers,

Laurin.