Bending verification of reinforced concrete elements in 6 steps.

Episode #4 of the Reinforced Concrete Series

Welcome back,

Bending is the verification I do the most when I design reinforced concrete elements.

You need to verify bending when you design beams, slabs, frames, foundation beams, pad and strip footings and many more structural elements.

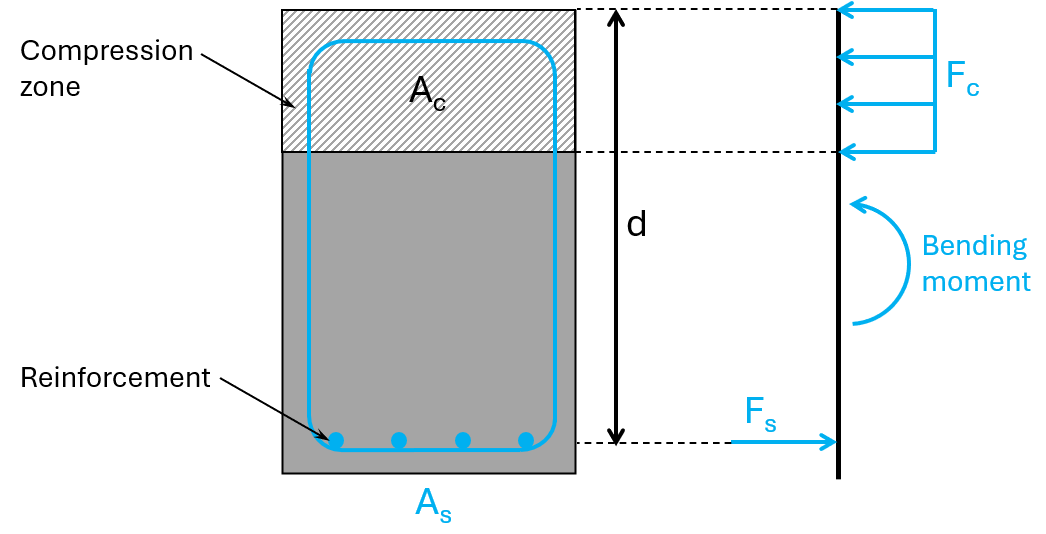

Concrete is great in compression but very weak in tension. The steel reinforcement is added to take up the tension forces. The bending moment of a rc cross-section is split up in a compression and a tension component, where the compression component is a compression zone taken up by the concrete and the tension force is taken up by the reinforcement as a tension force.

In this newsletter, I’ll show how you design and verify reinforced concrete elements like beams and slabs for a bending moment.

Curiosity > knowledge [thought of the week]

Over the last years, I worked with a lot of structural engineers. Some with a lot of experience, some just graduated, some had student jobs during their studies, some didn’t.

To me, there seems to be a pattern that the “best” engineers have.

The best engineers I worked with were at the same time the most curious ones. They don’t pretend to know it all.

They are life-long learners

They study in their spare time

They are obsessed about finding solutions

They are honest about what they don’t know

They share their knowledge with other and like to teach younger engineers

Structural engineering is so complex and every project demands new solutions. We simply can’t know it all.

But now let’s get back to the bending verification of rc elements..

The 6 steps to verify bending of reinforced concrete

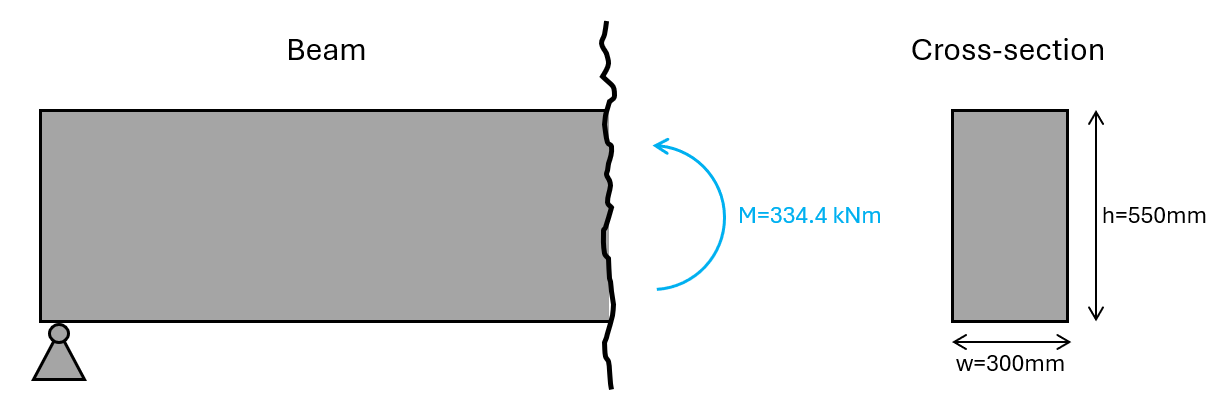

To run through the #6 steps to verify bending, we’ll use the following beam cross-section. You can apply this workflow also for slabs. Instead of the width of the beam in the formulas, use 1m.

In the literature, you can find many different formulas for the bending verification. The following formulas are the ones I use. Feel free to use different formulas if you want. Just know that there are options and the one I am presenting is not the one-and-only.

Also, every engineer has its own workflow. Some will first calculate the minimum reinforcement and other pick the reinforcement before they calculate the required reinforcement.

Therefore, feel free to swap around the following steps.

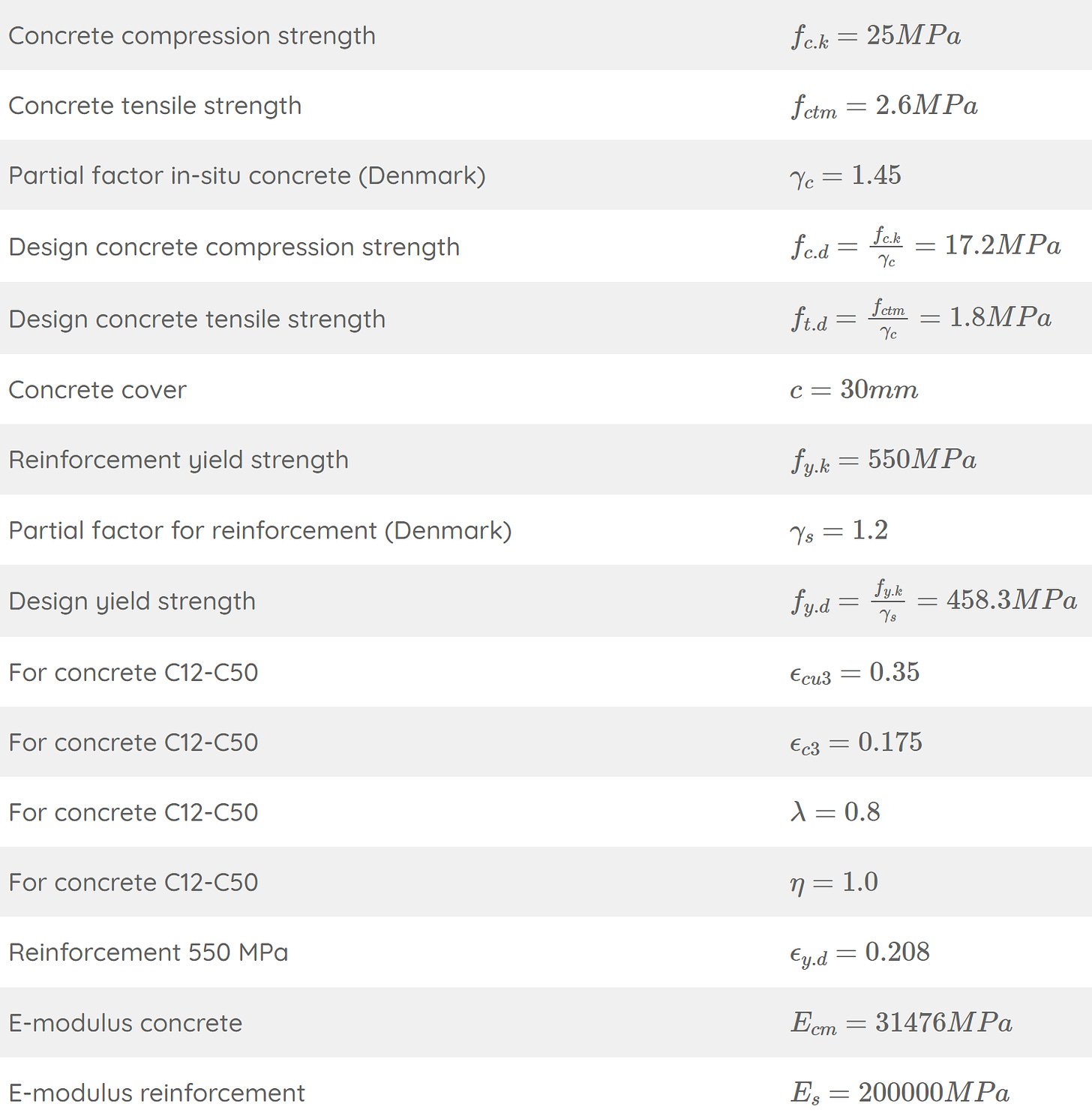

Step #1: Define the properties of concrete and reinforcement

In this tutorial, we’ll use the following concrete and reinforcement properties.

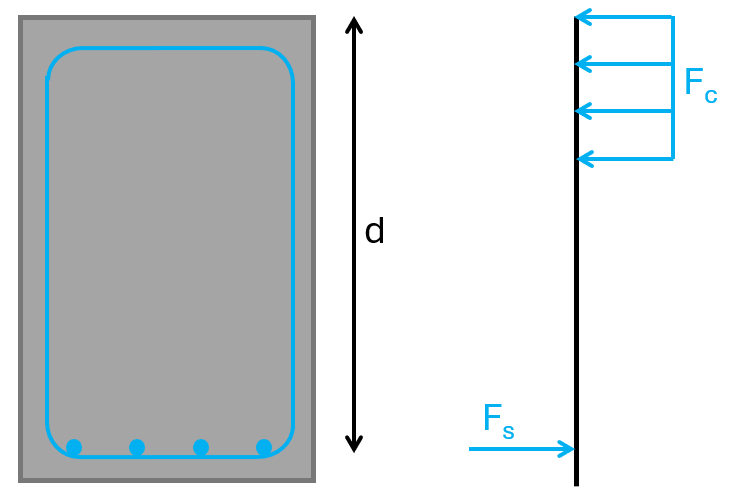

Step #2: Calculate the lever arm of the longitudinal reinforcement

The lever arm is the distance from the most outer concrete fibre in compression to the longitudinal reinforcement taking up the tension forces.

In our example (for a positive bending moment), we’ll get compression in the top and tension in the bottom.

Let’s assume the diameter of the longitudinal reinforcement is ds = 25 mm and the stirrups dv = 10 mm, then the lever arm is calculated as:

Step #3: Calculate the required longitudinal reinforcement to take up the tension force

The required reinforcement is calculated with the following formulas.

Required longitudinal reinforcement:

Step #4: Pick the diameter and amount of longitudinal reinforcement

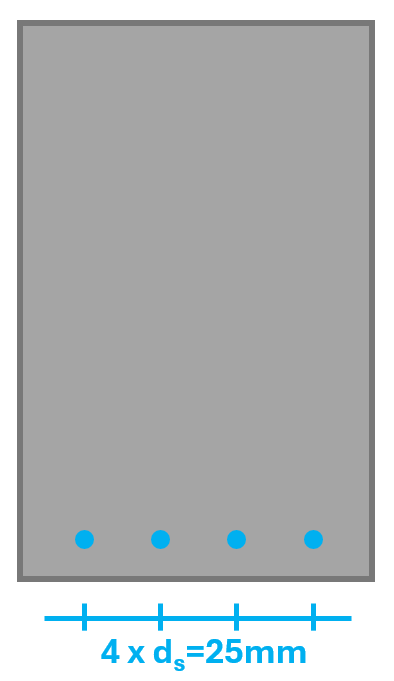

We picked a rebar diameter of 25 mm, which has a cross-sectional area of:

Next, we calculate the amount of rebars we need as a minimum to fulfill the required reinforcement demand:

Now, we can calculate the total reinforcement area for 4 rebars of diameter 25 mm.

Step #5: Verify the degree of reinforcement

Now, we basically verify that the cross-section is not over and underreinforced.

Verification:

Verification:

Verification:

Step #6: Verify the minimum reinforcement

The minimum reinforcement is calculated with EN 1992-1-1 9.2.1.1 (9.1N):

Now, comparing As with As.min shows that the minimum reinforcement is less than the reinforcement we get from 4 x d=25mm rebars.

Now, this was only the verification for the bottom longitudinal reinforcement. Don’t forget to also verify the reinforcement in the top. If you don’t have negative moments, it should at least have the minimum reinforcement.

Final words

The most important verification of reinforced concrete - bending - is in the books.

For many of you, this might have been repetition. But repetition is always good. It deepens your knowledge.

I also often gain new insights when I write and document these newsletters. Even though I have probably done this verification many times.

What happens in your day-to-day tasks as a structural engineer is that you use software for most verifications. So you actually don’t go through each step, we went through. But you definitely need to know what the software is doing.

Going through these hand calculations helps remember the formulas and fundamentals of reinforced concrete design. If we know the fundamentals by heart, we have a much better understanding of why a structure might not verify in a software program and how we can make it verify.

I’ll see you next Wednesday for part #5 of the reinforced concrete series. ✌️✌️

If you missed episodes #1 - #3 of this new series, then you can find all previous posts → here ←.

Thanks for reading today’s episode.

Cheers,

Laurin.

Enjoy the newsletter? Please forward to a friend you think could like our structural engineering content. It only takes 11 seconds. Making this one took a few hours. Just forward this link: https://www.structuralbasics.com/newsletter/

Nice one Laurin!

For Eurocode users, there's a very interesting open-source Python project based on capacity calculations called structuralcodes. Very well organized, I encourage those interested to check it out - I think this is one for the future.

https://github.com/fib-international/structuralcodes